INSIGNIS Technology Corporation

Introduction

The purpose of this page is to show how our proprietary test flow guarantees higher quality memory products with better reliability for industrial applications.

We will review the test flow process and show why Insignis grade memory has a longer product lifetime compared to standard grade memory.

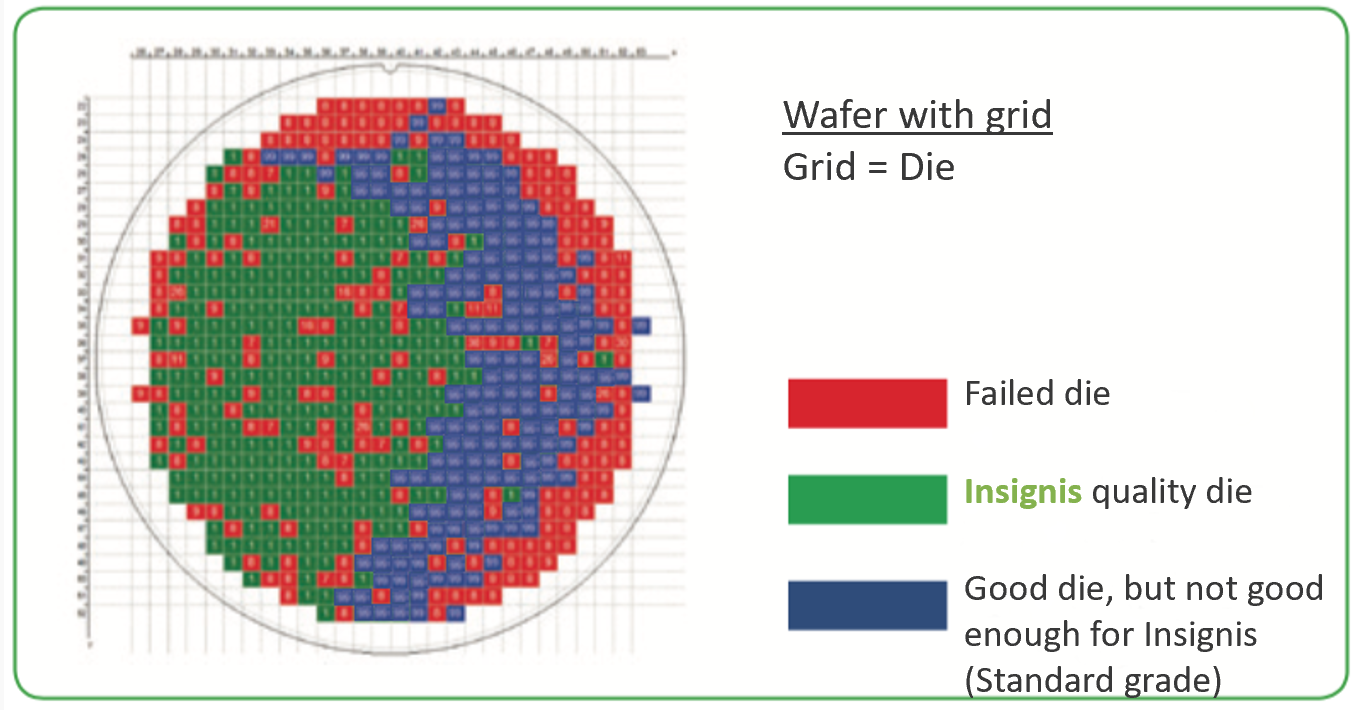

The Insignis test flow selects the die with the lowest defect density to give our customers the best quality and reliability product possible. We have a sophisticated algorithm that screens out die with defects and failure modes that are more likely to fail than the rest of the distribution. The good die on each wafer are further sorted into Insignis grade product and then standard grade product.

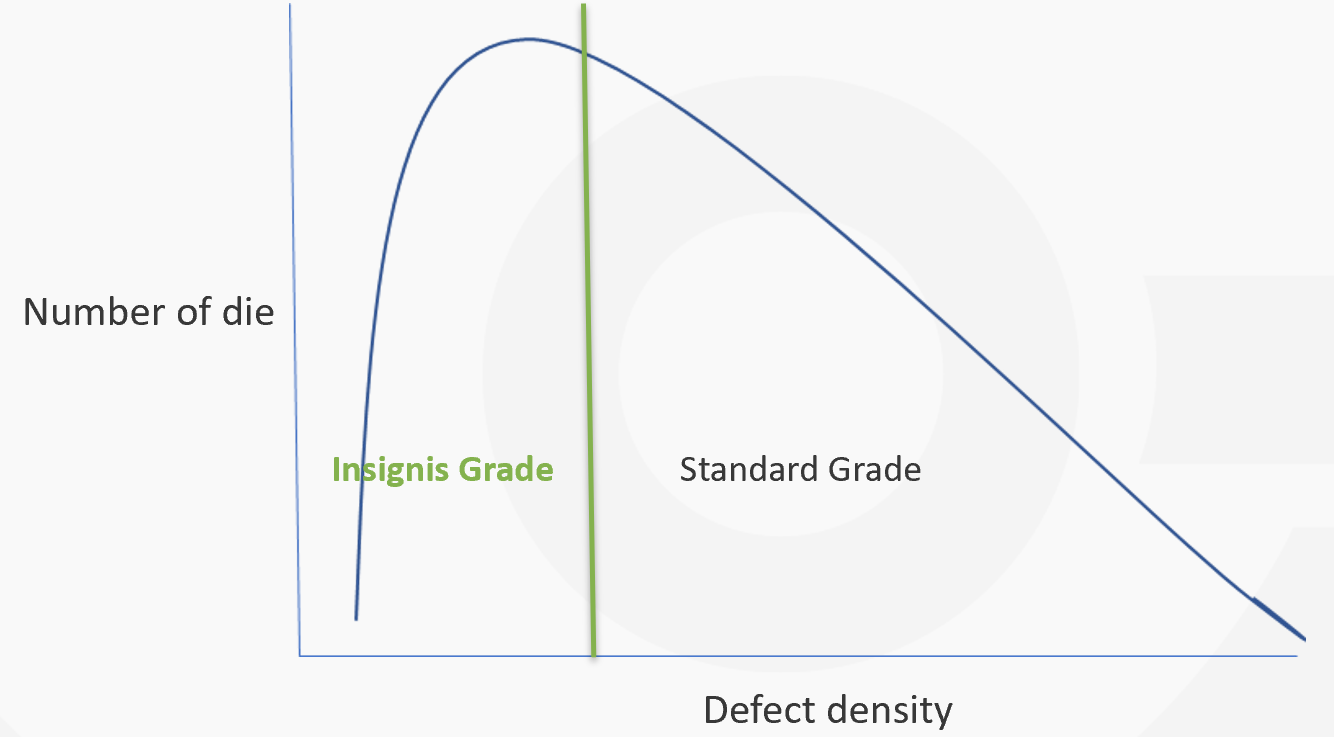

This graph shows the standard distribution of die on a wafer versus the defect density for each die. Every DRAM die requires repair in order to make it a passing die. The number of repairs and the location of the repairs are direct indicators for the defect density for each die.

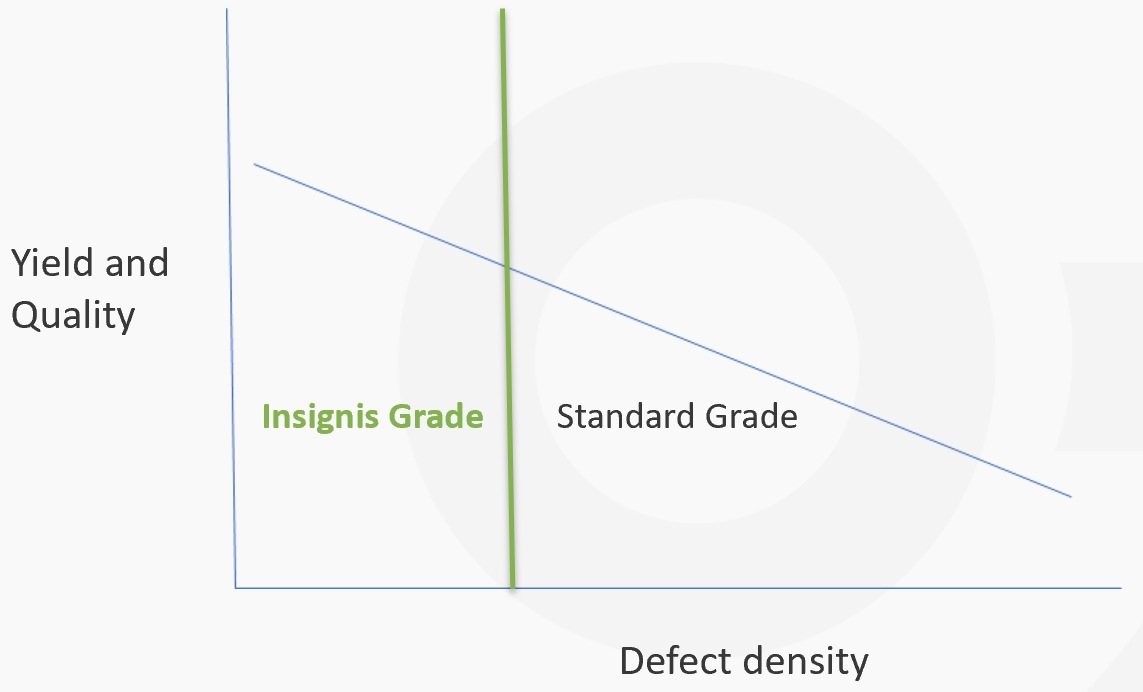

Yield, quality and reliability all trend directly with defect density. For the Insignis flow, we screen out the population of parts that have the lower yield and worse quality and reliability.

Die Selection

Insignis flow selects only the die from the high quality portion of each graph. Those die are shown as the green boxes on the wafer map.

Burn

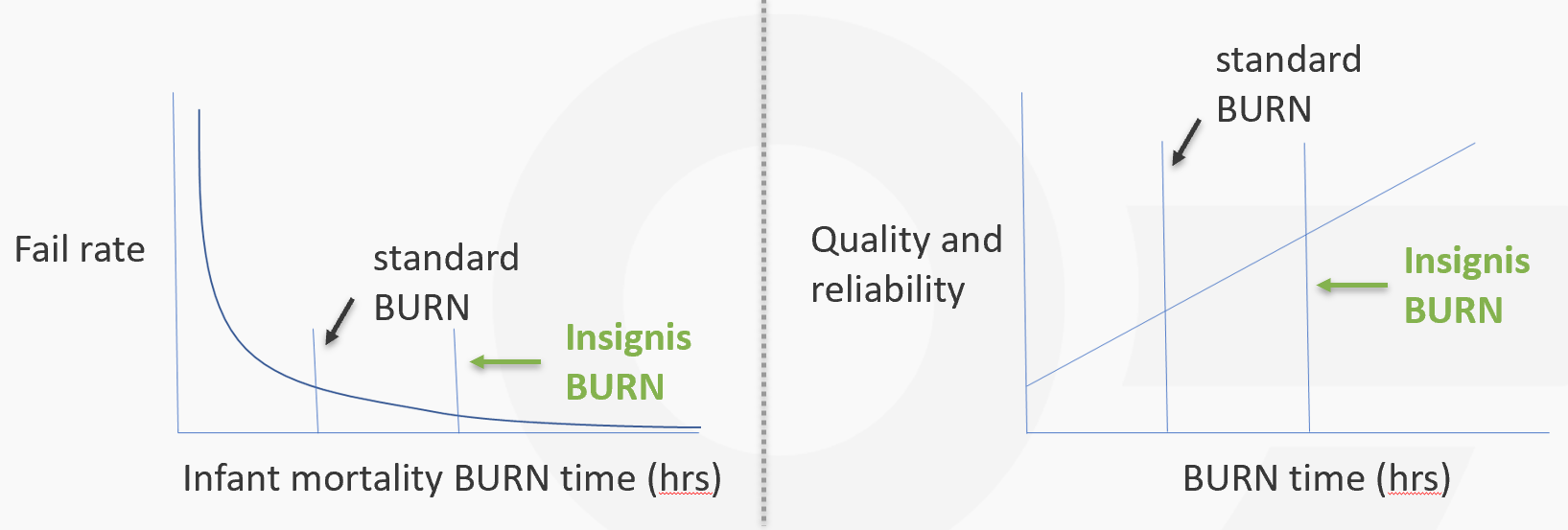

The standard BURN process targets a FIT (Failure In Time) rate for a population of parts. The standard product runs BURN to just meet that FIT target. The Insignis quality material runs an extended BURN time to further improve the population to give an even better FIT rate. Longer BURN times translate into a better quality and reliability experience for Insignis customers.

Guardband Testing

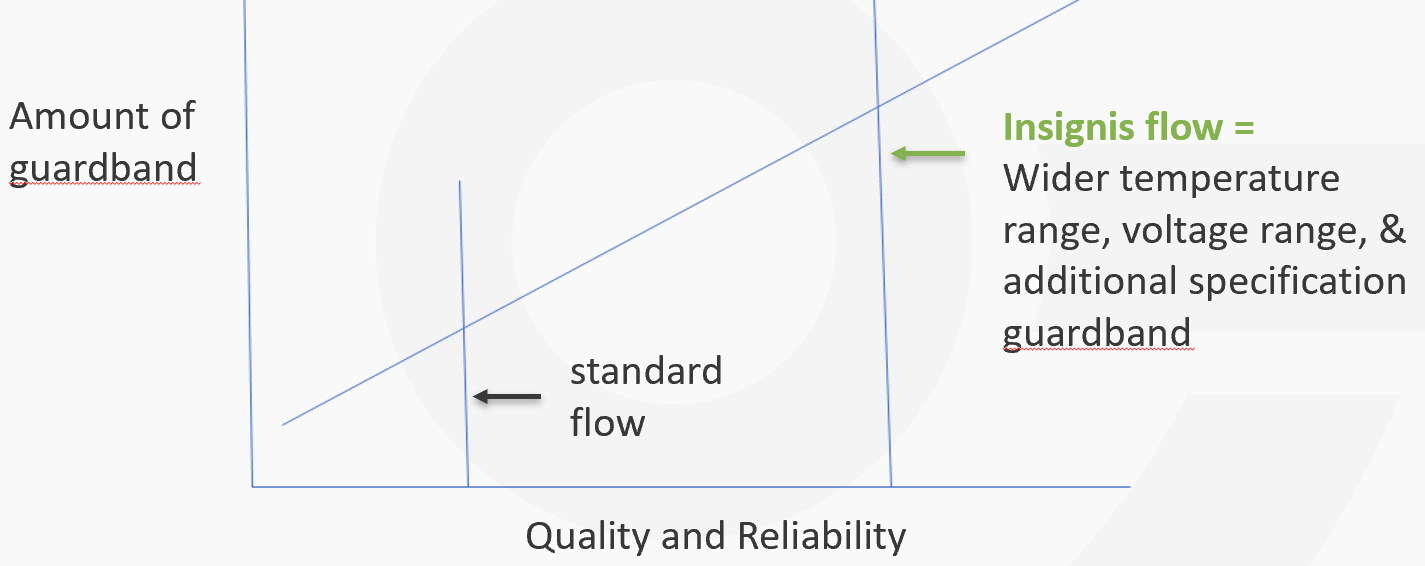

More guardband = Higher quality and reliability

Testing guardband builds in quality and margin into the product. The Insignis flow runs wider temperature guardbands as compared to the standard flow. The Insignis test flow also runs wider voltage and specification guardbands at every step to build in more quality into every die. These more stringent test conditions improve the overall quality and reliability of the population as compared to the standard test flows.

Conclusion

Insignis' proprietary, enhanced test flow is engineered to produce premium quality parts through our longer burn times, wider temperature ranges, and highly advanced lot, wafer, and die selection criteria.

Our ability to mitigate Early Life Failures allows our customers to avoid the risk of defects associated with standard grade memory.

For additional information about our Extended Test Flow, click here.